How does it work?

1. Sensor regularly acquires vibration data, shares it with a nearby router and data is moved to the cloud for analysis

2. Sonora cloud analytics algorithms immediately analyse collected data and creates actionable reports, insights and alerts

3. Developed insights are showcased on the web dashboard and alerts are shared via email/sm

Data analysis

The system uses advanced algorithms to detect consistent patterns while filtering out random vibration spikes, ensuring only genuine faults are reported. It operates autonomously without requiring equipment context or calibration, enabling immediate fault detection and timely maintenance decisions.

SONORA

QUICK AND EASY STARTUP

No contextual information about the equipment is required. The sensor can be installed in less than a minute.

DOWNTIME - 0 min

Plan your repair work at a convenient time when operations are not running. Reduce downtime due to mechanical joint failures to zero.

INFORMATION ABOUT FAULTS, NOT SHOCKS

The system informs you about real impending faults, not vibration shocks caused by random impacts around the equipment.

INSTANT ROI

Thanks to favourable pricing, the return on investment can be immediate, starting from the very first month of system use.

Need more information?

Contact UsMONITORED EQUIPMENT

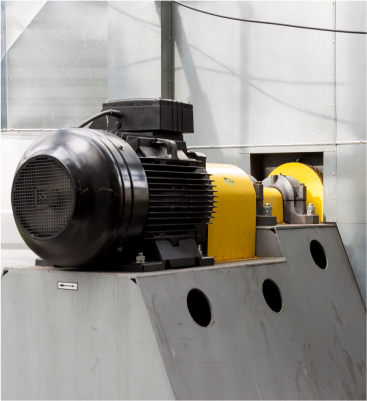

Motors

Gearboxes

Compressors

Fans

Pumps

Bearings

Asset overview

Access a summary of asset health statuses and group details for a quick assessment of the overall fleet condition.

Asset view

Explore detailed information about a specific asset, including health status and installation data for in-depth monitoring.

Raw Data and Features

Presentation of measurement data and features, allowing easy analysis of asset performance trends.

Defects Catalogue

Concise overview of identified defects, including notification and verification details, to monitor asset health effectively.

device

Sensor

gateway

CASE STUDIES

Need more information?

Contact usTHEY TRUST US