RUNNING ON THE EDGE. WHY THE RAILWAY SECTOR IS RETHINKING MAINTENANCE?

For more than a century, railway sector has been the backbone of industrial economies, moving freight, passengers and powering supply Read more...

THE PRICE OF SILENCE. WHY MACHINES FAIL WITHOUT WARNING?

In industrial environments, silence is often perceived as a sign of normal operations. Machines running without noise, vibration, or disruption Read more...

EARLY DETECTION OF WHEEL DEFECTS. A CASE STUDY ON COST SAVINGS, REPAIR OPTIMIZATION AND FLEET EFFICIENCY

Wheel defects, such as flat spots and cavities, are a frequent challenge in railway operations, leading to increased wear, operational Read more...

WAGON MAINTENANCE WITH POWERAIL. CASE STUDY IN COST SAVINGS AND OPERATIONAL EFFICIENCY

Railway companies face constant pressure to maintain fleet reliability while managing operational costs and minimizing downtime. One critical area of Read more...

THE GROWING ROLE OF RAILWAYS IN FREIGHT TRANSPORTATION

The global demand for efficient long-distance transport solutions is increasing, making rail freight more vital than ever. Railways play a Read more...

BEARING HEALTH MONITORING: ENSURING THE BACKBONE OF RAILWAY OPERATIONS

Wagon bearings play a pivotal role in railway operations. Bearing issues can lead to increased maintenance costs and safety risks. Read more...

FLATSPOTS – DETECTING AND ADDRESSING WHEEL DAMAGES WITH POWERAIL

One of the most critical concerns in the railway industry is the early identification of flatspots on train wheels. Flatspots Read more...

RAILWAYS OVER ROADS. SUSTAINABLE FREIGHT TRANSPORT

In the ever-evolving landscape of freight transport, making the right choice between railways and roads can significantly impact efficiency, cost, Read more...

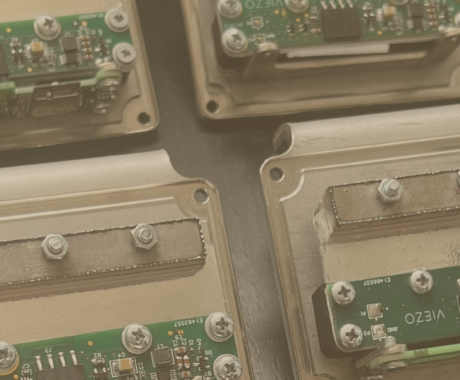

ADVANCING RAILWAY SENSOR TECHNOLOGY: THE BATTERY DILEMMA AND SUSTAINABLE SOLUTIONS

In the modern railway industry, sensors play a crucial role in ensuring safety, efficiency, and seamless operations. These sensors are Read more...